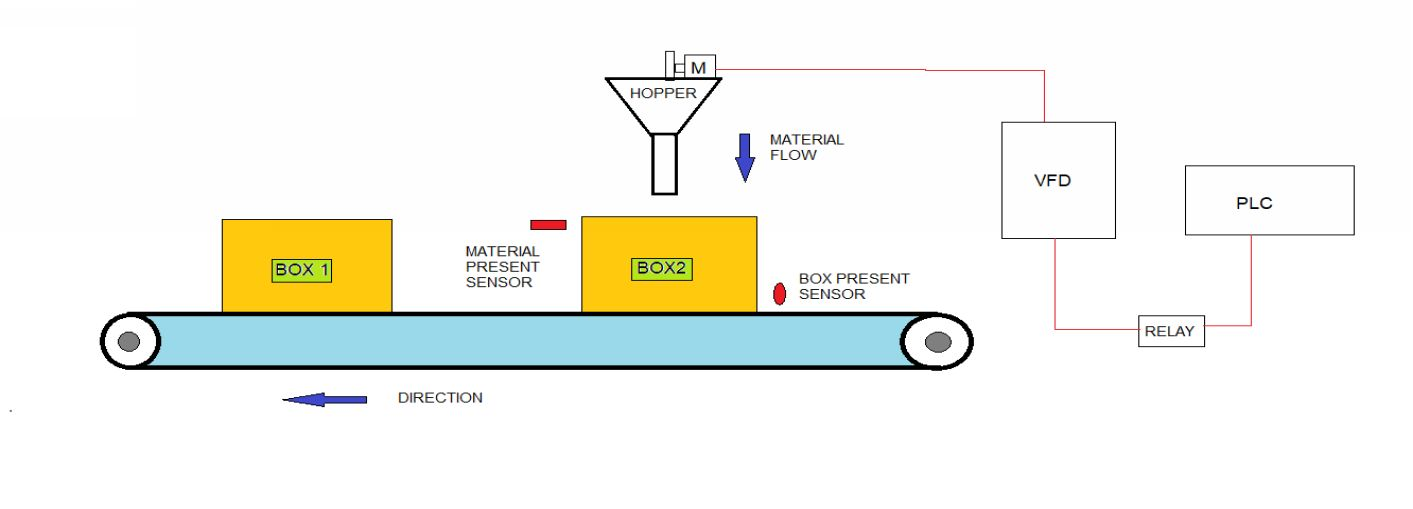

Conveyor application

A box filling line is as shown above. It consists of a flat belt conveyor which carries boxes and a hopper which fills powder into the box. Both conveyor and hopper are controlled by two different VFDs. The quantity of powder can be controlled by rotation of the motor through VFD.

A detects the presence of the box at the filling station and another detects the level of material filled into the box.

● When a start PB is pressed, the system starts.

● When a sensor detects the presence of a box, the controller stops the conveyor.

● After detecting the presence of a box, the hopper’s motor will start (1 sec delay) until a level sensor detects the presence of material.

● Once the box gets filled by powder, the controller will start the conveyor after 2 sec.

● This cycle will continue till stop PB is pressed.

Input and Output devices list

| Input devices | Output devices |

| Start PB | Conveyor motor |

| Stop PB | Hopper motor |

| Box present sensor | |

| Level sensor |

Heating application

When a start PB is pressed and if the boiler’s temperature is less than 40 deg cel, then all heaters (H1,H2,H3, and H4) will turn on.

If temperature is greater than 60 deg cel, then heater 1 gets off.

If temperature is greater than 75 deg cel, then heaters 1 and 2 get off.

If temperature is greater than 95 deg cel, then all heaters get off and switch on the fan.

Flash light

● When a button is pressed, a lamp gets on for 1 sec and gets off for 0.5 sec. The lamp will continue flashing for 20 sec.

● A lamp will not flash after pressing PB 5 times, it will reset by reset button only.

Home automation

● A controller is used to control the door, lamp, and a fan inside the room. A radar sensor is provided at entry of the room which detects the entry on an object or a human. When it detects anything, it sends a signal to the controller and the door starts sliding to the left side after 1 sec and gets closed after 3 sec.

● As soon as an object enters the room, the lamp will glow.

● If the temperature inside the room is higher than 38 deg cel, a fan will start. A digital temperature sensor is used to detect temperature inside the room, it sends a signal to the controller if the temperature is greater than 65 deg cel.

Shrink tunnel

A shrink tunnel consists of a conveyor that carries the parts through the tunnel. A part present sensor is provided at entry of the conveyor which detects the presence of part.

When a start PB is pressed, heaters will start heating and after 2 minutes a fan inside the tunnel will start circulating hot air. When heaters achieve 120 0 C inside the tunnel, a conveyor will start. This cycle will stop after pressing stop PB.

Production report

When the start PB is pressed after every 4 seconds a red marker is manufactured, and after every 7 seconds a black marker is manufactured. When total markers are manufactured in 7 and 9 quantities then the yellow lamp and red lamp will glow respectively.