Water level control

● The Inlet valve opens when the water level goes to the lower level of the underground tank and gets closed when the underground tank gets full.

● The pump starts only when the water level in the overhead tank goes to the lower level of the overhead tank.

● The pump stops when the overhead tank gets full or the water level in the underground tank goes to the lower level. I.e. The pump should not dry run.

Input and Output devices list

| Input Devices | Output devices |

| Start PB | Pump |

| Stop PB | Solenoid valve |

| OL1- Overhead sensor1 | |

| OL2- Overhead sensor2 | |

| UL1- Underground tank sensor1 | |

| UL2- Underground tank sensor2 |

Milk bottle filling and capping application

● Start the conveyor in auto mode. When a bottle present sensor 1 detects the bottle, the conveyor gets stopped and the controller turns on the valve. The milk starts pouring into the bottle up to a certain level, then the valve gets off and the conveyor starts again.

● When a bottle present sensor 2 detects the bottle, the conveyor gets stopped, and the capping piston operates, when a cap is detected by a sensor, the capping piston stops and the conveyor starts again.

● When a bottle present sensor 3 detects the bottle, the conveyor gets stopped, and the labeling piston operates, when a label is detected by a sensor, the labeling piston stops and the conveyor starts again.

● his cycle continues until a stop PB is pressed.

Input and Output devices list

| Input devices | Output devices |

| Start PB | Conveyor motor |

| Stop PB | Solenoid valve |

| Auto/Man switch | Capping piston |

| Bottle present sensor 1 | Label piston |

| Level sensor | SPARE |

| Bottle present sensor 2 | SPARE |

| Cap present sensor | SPARE |

| Bottle present sensor 3 | SPARE |

| Label present sensor | SPARE |

Packaging application

● Start PB is used to start the whole process.

● A photo Sensor is used to detect products. When a product approaches a sensor, the controller sends a signal to the robotic arm after 2 sec to pick up the product.

● Once the product count reaches 10, the controller sends the signal to the packaging unit.

| Input devices | Output devices |

| Start PB | Product pitch up command |

| Stop PB | Start packaging command |

| Product present sensor |

Weighing application

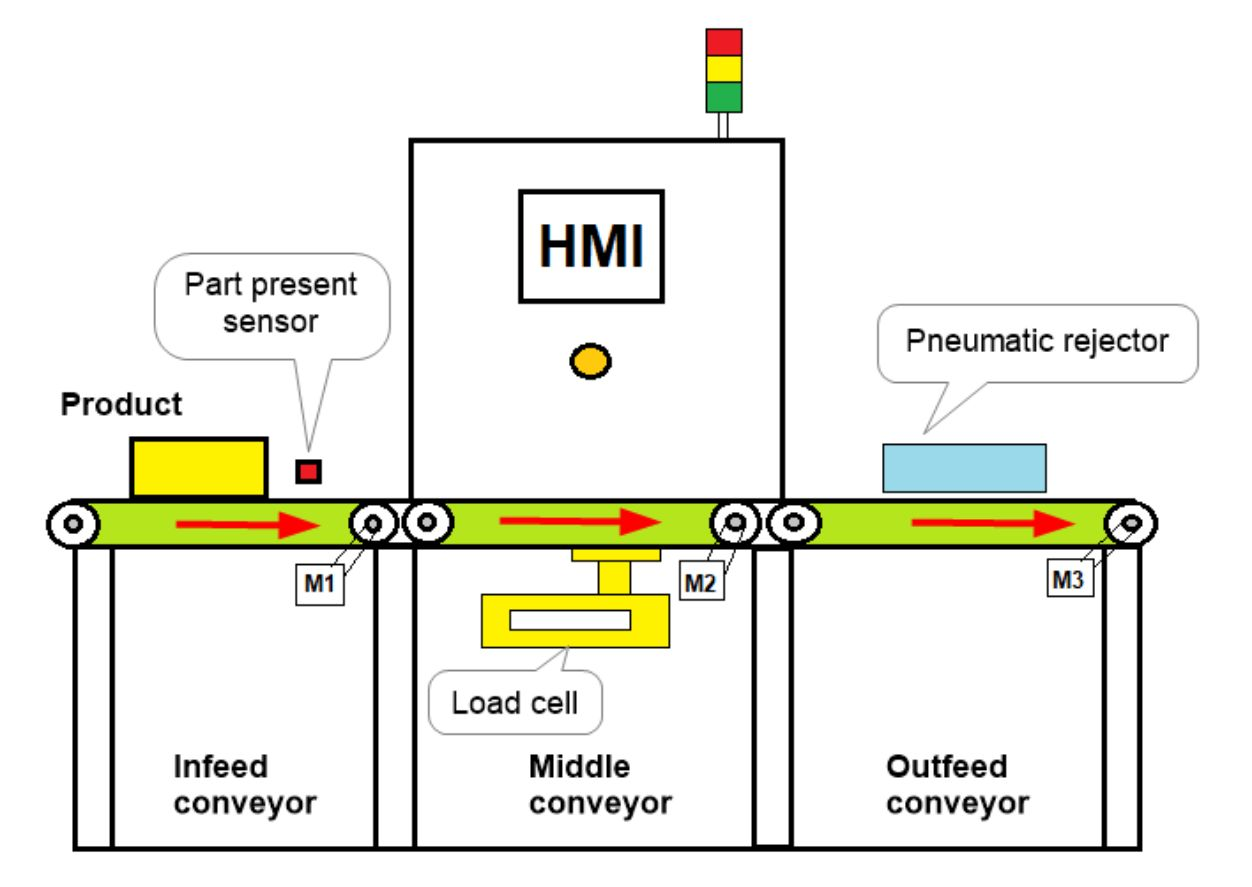

● A checkweigher consists of an infeed conveyor, middle conveyor with a load cell, and an output conveyor with a pneumatic rejector. A product present sensor is mounted on the infeed conveyor that detects the product.

● When a product passes over the middle conveyor, the load cell records the weight of the product during its travelling and sends signals to the PLC. The PLC receives three types of signals from the load cell (High weight, low weight, and accurate weight).

● If the product’s weight is OK, the product will pass from the checkweigher.

● But if the product’s weight is low or high, a pneumatic rejector will reject the product from the outfeed conveyor.

● If products are rejected 5 times, then a red lamp will glow.

Boiler application

● The boiler process starts when a start button is pressed from SCADA. If the level of water in the boiler is less than 20 ltr, the inlet valve will get on first and the centrifugal pump will get on after 3 sec. And they remain on until the water level reaches 80 ltr.

● Once the water level reaches 80 ltr, the pump and inlet valve will stop. The heater will start heating the water inside the boiler.

● As soon as the temperature reaches 110 degrees celsius, the heater will turn off. The outlet valve will be opened from SCADA to drain the boiled water.

● The outlet valve remains open until the water level reaches 20 ltr.

● This cycle continues until a stop button is pressed.

Input and Output devices list

| Input devices | Output devices |

| Temperature sensor | Inlet valve |

| Level sensor | Outlet valve |

| Centrifugal pump |