Scope of work

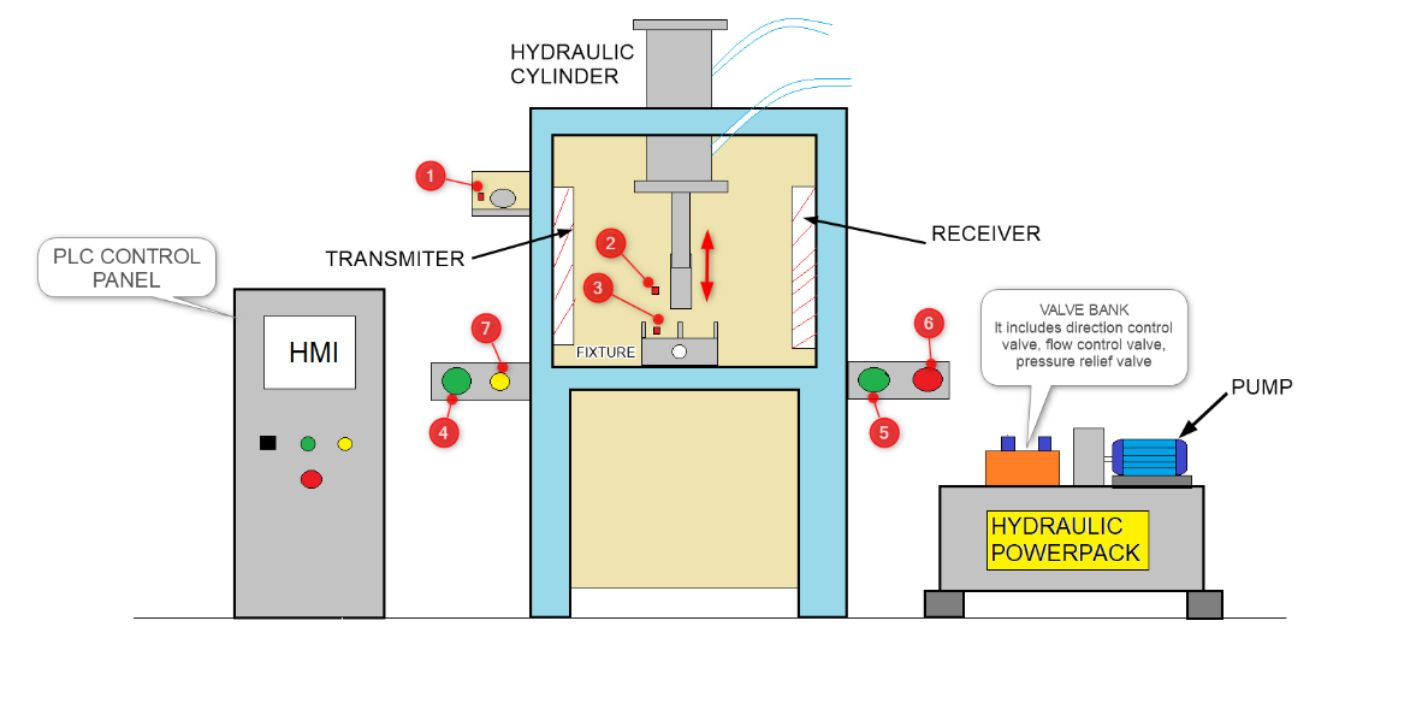

As shown in the above image, we have to press two LM bearings into the fork. Of Course we can go for a hammer or any mechanism, but customer needs these forks in huge numbers. So we provide him with a hydraulic press machine which will work effectively and save time as well as effort.

Hydraulic press machine

Input and Output devices list

| Input devices | Output devices |

|

Pump on |

|

Hydraulic cyl UP sol coil |

|

Hydraulic cyl DOWN sol coil |

|

Operation complete lamp |

|

SPARE |

|

SPARE |

|

SPARE |

| Safety light curtain | SPARE |

Hardware and software details

PLC – AB micrologix 1400

HM I- Panelview

PLC & HMI communication – Ethernet

Pump Motor contro l- Hardwired (via contactor)

Operation

● Keep the fork on the fixture properly, (part present sensor detects the fork).

● Take a LM bearing, sense it to the POKA YOKE sensor and then attach it below the hydraulic ram, (bearing present sensor detects the bearing).

● When the machine is in auto mode and there is no fault, a machine should start after pressing both palm PBs simultaneously. Switch on the cylinder DOWN solenoid coil for 5 sec, after completion of 5 sec, switch on the cylinder UP solenoid coil.

● Take another LM bearing, sense it to the POKA YOKE sensor, attach it to the ram, and press both palm PBs simultaneously. A lamp must glow after the completion of the cycle.

● If someone tries to interrupt machine operation (light curtain gives signal) a machine must stop immediately.

● A POKA YOKE sensor operation cannot be bypassed.